|

Siemens expands Scada software into plant-wide information system

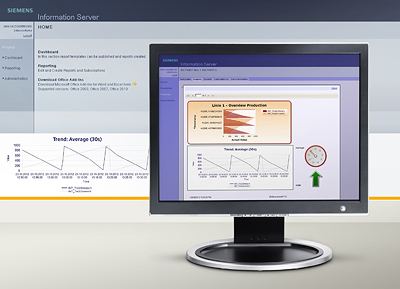

With Version 7.2 of its Simatic WinCC Scada software for the acquisition, visualization, and analysis of production data, the Siemens Industry Automation Division has expanded the software into a plant-wide information system. The new version also supports multitouch operator input concepts. The new Simatic Process Historian and Simatic Information Server options for Simatic WinCC V7.2 also offer users scalable long-term archiving of process data, as well as powerful, Web-based analysis and reporting tools. Both options include plant-wide analyses and reports, thus providing the basis for optimizing the production process.

Simatic WinCC Scada software

In the new Version 7.2, users can adapt the Simatic WinCC Scada system to even larger systems than previously with up to 18 optionally redundant servers. The archiving function automatically creates weekly, monthly and annual archives in accordance with the selected business management periods. As well as process values, the values of consumption counters and those of manual entries, such as lab values, can be recorded, analyzed and archived. For global use, Simatic WinCC 7.2 supports the Unicode data format, and individual language selection by the user. Users select their preferred language for local display or for operator input over the Internet, regardless of the language setting of the operating system. In addition, Simatic WinCC Version 7.2 supports operator input via two-finger multitouch gestures, with the usual gestures used on consumer devices such as zooming, sweeping, and rotating. This is designed to make operation of complex production plants more intuitive and simpler. Setpoint inputs can also be implemented. For safety reasons, these are designed as two-handed operations to protect users against unintentional switching operations.

Simatic Process Historian acquires and archives data from any number of lower-level WinCC systems in real time. The scalable software can be adapted to the required data volume at any time – without interrupting production. With Simatic Information Server, reports and analyses can easily be created, managed, and made available via Web-based interfaces. Based on Microsoft Reporting Services, users transparently access all the data archived in WinCC or Simatic Process Historian without the need for any programming know-how. Depending on the task – management, quality assurance, or maintenance – users compile the required plant data individually for reports and analyses. Add-ins in Word and Excel are additionally available for Microsoft Office

analyses. More: www.siemens.com/wincc

Source: Gerhard Stauss, Industry Automation Division, Siemens AG, November 2013

www.siemens.com

|

PennEnergy

Weekly Newscast

.

+

+ Media Links + +

For more information, media details or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|