|

Siemens

has installed first offshore platform in the North Sea (Pictures

Gallery)

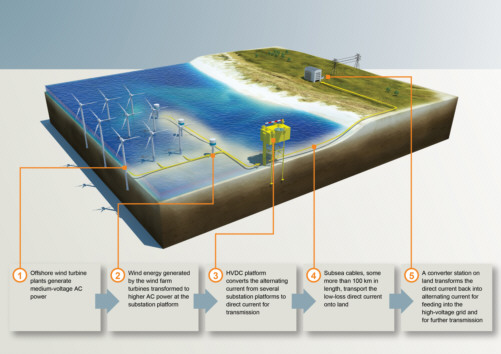

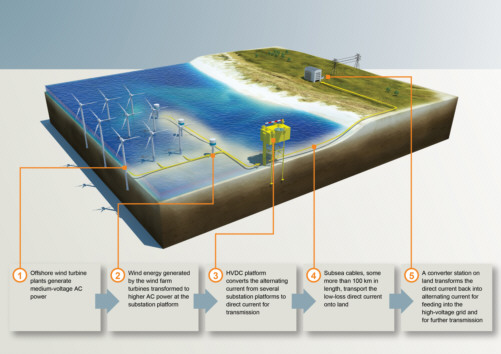

When the HelWin1 converter platform goes online, it will link the Nordsee Ost and Meerwind wind power plants to the mainland. The platform will convert up to 576 megawatts (MW) of electricity produced in the wind farms to direct current and transmit it via submarine cable to the German mainland 85 kilometers away. The low-loss direct current power is then converted back into alternating current at a converter station on land and fed into the German power grid. Thanks to Siemens direct current technology, transmission losses are less than four percent.

HVDC technology pays off

High-voltage direct-current (HVDC) transmission technology is used to convert the AC power produced in the wind farms to low-loss direct current. To accomplish this, several substations distributed throughout the wind farm transform the generated AC before it is converted to DC power by an HVDC platform. The electricity is transported onto land by a submarine cable, where it is converted back into AC. This technology is vital for cable lengths of more than 80 kilometers, as otherwise the transmission losses would be too great.

Substructure already installed in June Substructure already installed in June

The HelWin1 offshore platform is installed on a supporting substructure. This substructure alone weighs 1,000 tons. It left the shipyard in June and was anchored in the North Sea, which is 23 meters deep at this location, using ten steel piles. |

Fitters

difficult to recognize More than 100 employees are involved in the installation at sea. They are difficult to recognize (front, left in photo) next to the steel piles, which are up to 100 meters in length, with a diameter of up to 3.2 meters and a wall thickness of 8 centimeters. Fitters

difficult to recognize More than 100 employees are involved in the installation at sea. They are difficult to recognize (front, left in photo) next to the steel piles, which are up to 100 meters in length, with a diameter of up to 3.2 meters and a wall thickness of 8 centimeters. |

As tall as Big Ben As tall as Big Ben

The steel piles are anchored in the seabed at the installation location, 20 kilometers northwest of Helgoland. Up to 100 meters long, they are as tall as the famous London landmark Big Ben and provide secure anchoring for the platform.

|

Crew remains on site Crew remains on site

As the fitters start doing their work, the pilings’ size becomes visible: there’s space for six people working side by side (pictured). An on-site jack-up platform serves as the crews’ quarters so that they do not have to travel back to the mainland each day. This saves a great deal of time, since the platform is located 85 kilometers from the German coast. The time needed for this journey is around two hours by helicopter and 16 hours by ship.

|

Platforms with unmatched dimensions Platforms with unmatched dimensions

Siemens is currently working on four HVDC platforms, with HelWin1 being the smallest of the four. The individual platform weighs more than 20 fully loaded and fueled Airbus A380 super airliners and is 75 meters long and 50 meters wide, with a surface area of 3,750 square meters. This is more than half the size of a standard soccer field (7,140 square meters). Seven decks are distributed over its total height of 27 meters.

|

Combined efforts Combined efforts

Three tugboats are needed to tow the converter platform, weighing 11,000 tons, to its location off the coast of Helgoland. Since this steel giant is too large for passage through the North Sea/Baltic Sea (Kiel) canal, it had to be towed around the northern tip of Denmark. After seven days at sea, covering 990 kilometers, HelWin1 finally reached its installation destination. |

After the HVDC platform HelWin1 reached its setup zone a further four days were required for installation. HelWin1 is a floating jack-up platform that is moved to the desired position by tugboats with its supports raised. When it reaches this position, the supports are lowered and connected to the supporting structure that has already been installed. The platform is then raised using a hydraulic jacking system. After the HVDC platform HelWin1 reached its setup zone a further four days were required for installation. HelWin1 is a floating jack-up platform that is moved to the desired position by tugboats with its supports raised. When it reaches this position, the supports are lowered and connected to the supporting structure that has already been installed. The platform is then raised using a hydraulic jacking system. |

Protection against giant waves Protection against giant waves

The offshore platform is fixed at a height of 22 meters above sea level to protect it even against giant waves and the rough seas they produce. HelWin1 is designed for decades of operation in the rugged North Sea and will be monitored and controlled from land when it has been commissioned.

|

|

|

|

Offshore wind power and grid connections for the energy transition

As part of its new energy policy, the Federal German government plans to expand the installed offshore wind capacity from its current 200 megawatts (MW) to ten gigawatts (GW) by 2020. Expansion of offshore grid connections and the power grids on land is also required for low-loss transport of the electricity onto land and distribution to urban centers throughout southern Germany. Siemens is constructing four offshore grid connections in the North Sea with a capacity of around three GW as part of its contribution to making the energy transition a reality.

Source: Siemens presspictures.cc@siemens.com

Back to >

Siemens

succesfully installs first North Sea platform |

|

.

Worldwide more than 100,000

paid subscriptions

Technical

Briefs

from the editors of

Oil & Gas Journal

and Offshore Magazine:

Click

here ... and see what we have designed, produced, published and promoted for WIKA

and FMC Technologies ... and what we would like to do for you.

.

PennEnergy

Weekly

Video News

.PennWell Petroleum Group:

OGJ - Oil & Gas Journal

OGJ_eNewsletter

Offshore Magazine

Offshore eNewsletter

Oil & Gas Financial Journal

Oil, Gas & Petrochem

OGJ Russia

OGJ LatinoAmericana

PennEnergy

PennEnergy-eNewsletter

+ + +

For more information, media

kits or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|

Substructure already installed in June

Substructure already installed in June Fitters

difficult to recognize More than 100 employees are involved in the installation at sea. They are difficult to recognize (front, left in photo) next to the steel piles, which are up to 100 meters in length, with a diameter of up to 3.2 meters and a wall thickness of 8 centimeters.

Fitters

difficult to recognize More than 100 employees are involved in the installation at sea. They are difficult to recognize (front, left in photo) next to the steel piles, which are up to 100 meters in length, with a diameter of up to 3.2 meters and a wall thickness of 8 centimeters.  As tall as Big Ben

As tall as Big Ben Crew remains on site

Crew remains on site Platforms with unmatched dimensions

Platforms with unmatched dimensions Combined efforts

Combined efforts After the HVDC platform HelWin1 reached its setup zone a further four days were required for installation. HelWin1 is a floating jack-up platform that is moved to the desired position by tugboats with its supports raised. When it reaches this position, the supports are lowered and connected to the supporting structure that has already been installed. The platform is then raised using a hydraulic jacking system.

After the HVDC platform HelWin1 reached its setup zone a further four days were required for installation. HelWin1 is a floating jack-up platform that is moved to the desired position by tugboats with its supports raised. When it reaches this position, the supports are lowered and connected to the supporting structure that has already been installed. The platform is then raised using a hydraulic jacking system. Protection against giant waves

Protection against giant waves