|

MAN supplies compressor technology for a major project for the production of synthetic fuels in China

MAN Diesel & Turbo has been awarded the contract for a major project to construct eleven turbomachinery trains in China. The contract value is in excess of 125 million Euro.

The site of the project is Yinchuan in the Ningxia region where air separation plants are being built under the management of

Linde and Hangyang for one of the world’s largest coal liquefaction production plants, a so-called coal-to-liquid plant. This means it will be possible to utilize the rich coal resources of the region to produce fuels and other hydrocarbons.

The chemical process used requires huge quantities of oxygen. The turbomachinery ordered will be used in an air separation plant which will generate about 40,000 tons of oxygen from the atmosphere daily.

The plant is operated by the Shenhua Ningxia Coal Industry Group Co.,Ltd.

“This major contract is confirmation that we have identified today’s demands for such mega-plants at an early stage and responded accordingly“, says Dr. René Umlauft, CEO of MAN Diesel & Turbo, with delight. “The MAX1 axial compressor used in all eleven machine trains was the most challenging compressor development project in the company’s history and has proved its worth yet again.“

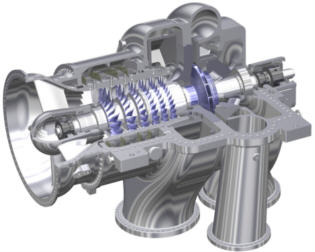

Each machine train consists of three different MAN products: a six-stage MAX1 axial/centrifugal compressor type AR115/06M with high-pressure radial component, an also six-stage integrally geared compressor type RG 56-6 and a condensing steam turbine DK080/250R, acting as the driver for both compressors.

The MAX1 axial compressor is regarded as a technical landmark - the result of several years of intensive development work that was completed in 2011. Together with German partner MTU Aero Engines, Munich, MAN Diesel & Turbo has combined for the first time in this configuration the advantages of industrial compressors – robust design and high efficiency – with the advantage of gas turbine compressors and aircraft engines, the exceptionally high power

density.

Source:

Monika Koenig-Speckamp

MAN Diesel &

Turbo SE

www.man.eu

24.04.2013

|

PennEnergy

Weekly

Video News

.

Oil

& Gas Journal:

Worldwide more than 100,000

paid subscriptions

Learn

more

.

OGJ

Executive Briefs

.PennWell Petroleum Group:

OGJ - Oil & Gas Journal

OGJ_eNewsletter

Offshore Magazine

Offshore eNewsletter

Oil & Gas Financial Journal

Oil, Gas & Petrochem

OGJ Russia

OGJ LatinoAmericana

PennEnergy

PennEnergy-eNewsletter

+ + +

For more information, media

kits or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|