|

Methanation reactor from MAN produces Audi e-gas

Cooperation within the VW Group points out the potential of this renewable fuel

on an industrial scale for the first time

While the change in energy policy is being discussed in many places, MAN and Audi are creating facts. The vehicle manufacturer will produce and feed synthetic methane (Audi e-gas) into the public natural-gas network starting summer 2013. The core component of the plant, which is being built in cooperation with equipment manufacturer SolarFuel GmbH in Werlte (Emsland region), is an MAN Diesel & Turbo methanation reactor. Construction and production of the e-gas plant unit that is around 16 meters high was constructed and produced by MAN’s specialists for chemical and physical reactors at its Deggendorf site. In December 2012, a heavy-duty transport took the ready-for-use tower to Werlte which is 782 kilometers away.

While the change in energy policy is being discussed in many places, MAN and Audi are creating facts. The vehicle manufacturer will produce and feed synthetic methane (Audi e-gas) into the public natural-gas network starting summer 2013. The core component of the plant, which is being built in cooperation with equipment manufacturer SolarFuel GmbH in Werlte (Emsland region), is an MAN Diesel & Turbo methanation reactor. Construction and production of the e-gas plant unit that is around 16 meters high was constructed and produced by MAN’s specialists for chemical and physical reactors at its Deggendorf site. In December 2012, a heavy-duty transport took the ready-for-use tower to Werlte which is 782 kilometers away.

Its ability to produce carbon neutral fuel from renewable electricity makes this facility special. Audi e-gas can be stored and transported with infrastructure currently available as it is nearly identical to fossil-based natural gas chemically speaking. As such, it can easily be distributed via the natural gas network as well as delivered to CNG stations.

“This order stresses once more our competence in building chemical apparatus with the aid of which synthetic fuel can be produced,” said Dr. Josef Dachs, Head of MAN Diesel & Turbo’s site in Deggendorf. “Whether we are talking about the Pearl in Qatar, the largest gas-to-liquids plant in the world operated by Shell, or Audi’s e-gas project in the Emsland: Our know-how is in demand worldwide when it comes to finding and providing solutions for the future’s mobility.”

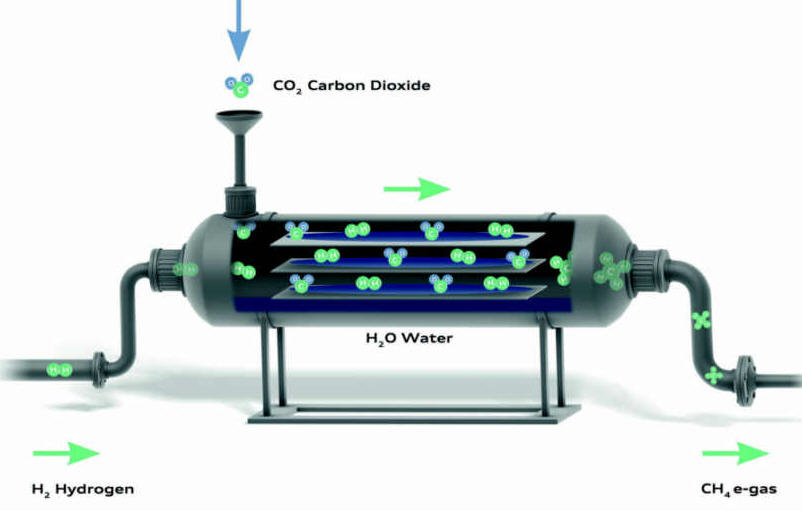

At Audi’s plant, electricity from wind or solar energy is converted into e-gas in two major steps. In the first, the electricity is used for electrolysis. This process splits water (H2O) molecules into oxygen (O2) and hydrogen (H2). The hydrogen then reacts with carbon dioxide (CO2), itself being a waste product from a nearby biogas plant, to become methane (CH4).

The dual electricity / gas principle of Audi’s e-gas project is a practical example of how to make good use of the wind energy excess on stormy days when the existing German grid is insufficient to carry the load. The Werlte facility will generate enough CO2-neutral e-gas to power 1,500 CNG cars over 15,000 kilometers every

year.

Source: Monika König, MAN Diesel & Turbo SE - www.mandieselturbo.com

25.01.2013

|

PennEnergy

Weekly Newscast

.

+

+ Media Links + +

Oil

& Gas Journal:

Worldwide more than 100,000

paid subscriptions

Learn

more

For more information, media details or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|

While the change in energy policy is being discussed in many places, MAN and Audi are creating facts. The vehicle manufacturer will produce and feed synthetic methane (Audi e-gas) into the public natural-gas network starting summer 2013. The core component of the plant, which is being built in cooperation with equipment manufacturer SolarFuel GmbH in Werlte (Emsland region), is an MAN Diesel & Turbo methanation reactor. Construction and production of the e-gas plant unit that is around 16 meters high was constructed and produced by MAN’s specialists for chemical and physical reactors at its Deggendorf site. In December 2012, a heavy-duty transport took the ready-for-use tower to Werlte which is 782 kilometers away.

While the change in energy policy is being discussed in many places, MAN and Audi are creating facts. The vehicle manufacturer will produce and feed synthetic methane (Audi e-gas) into the public natural-gas network starting summer 2013. The core component of the plant, which is being built in cooperation with equipment manufacturer SolarFuel GmbH in Werlte (Emsland region), is an MAN Diesel & Turbo methanation reactor. Construction and production of the e-gas plant unit that is around 16 meters high was constructed and produced by MAN’s specialists for chemical and physical reactors at its Deggendorf site. In December 2012, a heavy-duty transport took the ready-for-use tower to Werlte which is 782 kilometers away.