|

Breakthrough in offshore compression

MAN's first hermetically-sealed motor compressor unit for an offshore

platform

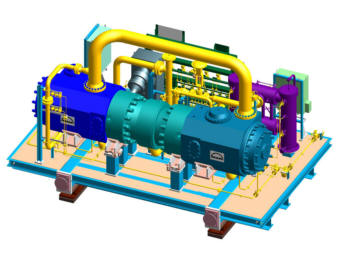

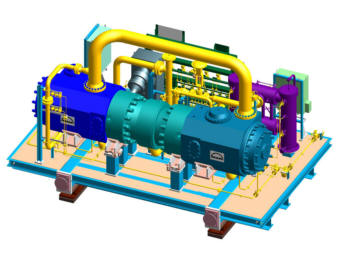

MAN Diesel & Turbo in Zurich was awarded a contract for a HOFIM®

compressor (High-Speed, Oil-Free, Integrated Motor). This is a significant

business milestone: It is MAN's

first hermetically-sealed compressor being

installed on an offshore production platform Ivar Aasen in the North

Sea, run by Det norske oljeselskap ASA.

"From a conceptual point of

view, this HOFIM® compressor unit is very similar to MAN's subsea

compressors currently being under system integration tests in Norway",

states Mathias Scherer, Vice President Sales & Contracts in Zurich.

"This compressor technology has a great business potential for platform

operators as the offshore industry is asking for simple, robust and safe

systems which can be integrated into cramped environments. Another

important aspect is the improvement of total cost of ownership." "From a conceptual point of

view, this HOFIM® compressor unit is very similar to MAN's subsea

compressors currently being under system integration tests in Norway",

states Mathias Scherer, Vice President Sales & Contracts in Zurich.

"This compressor technology has a great business potential for platform

operators as the offshore industry is asking for simple, robust and safe

systems which can be integrated into cramped environments. Another

important aspect is the improvement of total cost of ownership."

MAN's Business Unit Oil & Gas has pioneered the development of integrated

turbocompressor systems in the past 25 years. The most significant aspects

of this machine are the use of a high-speed motor and active magnetic

bearings. There is no need for dynamic seals which makes the compressor

system hermetically sealed and as a consequence offers many advantages.

The absence of the dry gas seal system and of the complete oil system

reduces the complexity and this leads to the improved system reliability.

The required footprint significantly shrinks by 60 percent and weight on

the compressor installation drops by 30 percent in mass compared to

traditional compressor designs.

The order for Ivar Aasen comprises

a multi-stage radial compressor (1x100 percent) arranged in tandem

configuration around a centrally positioned 9.5 megawatts high-speed

electrical motor.

The integrated active magnetic bearings are

provided by MECOS, a company acquired by MAN Diesel & Turbo early 2012.

MECOS is a leading company in the field of active magnetic bearing

systems. Since 1988, MECOS has launched magnetic bearing solutions for

compressors, turbines and other high-speed rotating machinery serving in

various industrial applications. (

See more about HOFIM® Technology )

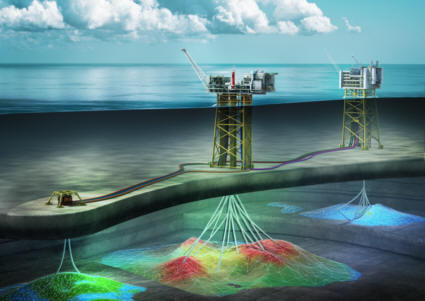

The complete HOFIM® unit will be

delivered to the module packager SMOE Pte Ltd. in Singapore which is

building the Ivar Aasen platform. In 2016 the module will be sailed away

to the final site of operation: The Ivar Aasen field situated in the

Norwegian sector of the North Sea. The compressor will export the produced

gas from the platform to shore.

Source: Martin Westerhoff

MAN

Diesel Turbo SE

www.mandieselturbo.com

Jan 15, 2014

|

Worldwide more than 100,000 paid subscriptions

PennWell

Petroleum Group:

OGJ - Oil & Gas Journal

OGJ_eNewsletter

Offshore Magazine

Offshore eNewsletter

Oil & Gas Financial Journal

Oil, Gas & Petrochem

OGJ Russia

Offshore Russia

OGJ LatinoAmericana

PennEnergy

PennEnergy-eNewsletter

+ + +

.

PennEnergy

Weekly

Video News

.

+ + +

For more information, media

kits or

sample copies please contact

wilhelms@pennwell.com

www.sicking.de

|

"From a conceptual point of

view, this HOFIM® compressor unit is very similar to MAN's subsea

compressors currently being under system integration tests in Norway",

states Mathias Scherer, Vice President Sales & Contracts in Zurich.

"This compressor technology has a great business potential for platform

operators as the offshore industry is asking for simple, robust and safe

systems which can be integrated into cramped environments. Another

important aspect is the improvement of total cost of ownership."

"From a conceptual point of

view, this HOFIM® compressor unit is very similar to MAN's subsea

compressors currently being under system integration tests in Norway",

states Mathias Scherer, Vice President Sales & Contracts in Zurich.

"This compressor technology has a great business potential for platform

operators as the offshore industry is asking for simple, robust and safe

systems which can be integrated into cramped environments. Another

important aspect is the improvement of total cost of ownership."